In-Slab Floor Boxes: What They Are, How They’re Used, and Why They Matter

When it comes to providing power and communications access in modern buildings, there are several types of floor boxes to choose from. Among the most common are poke-throughs and in-slab boxes. While both provide outlets and data connections right where people need them, they are not the same.

Poke-throughs are installed by coring through an existing concrete slab and inserting the box from below. In-slab floor boxes, on the other hand, are installed within the slab itself at the time of construction. They don’t “poke through” from one level to another; instead, they become a permanent, integrated part of the floor.

This article explains what in-slab floor boxes are, how they differ from poke-throughs, how they are installed, and the wide variety of applications where they are used.

What Is an In-Slab Floor Box?

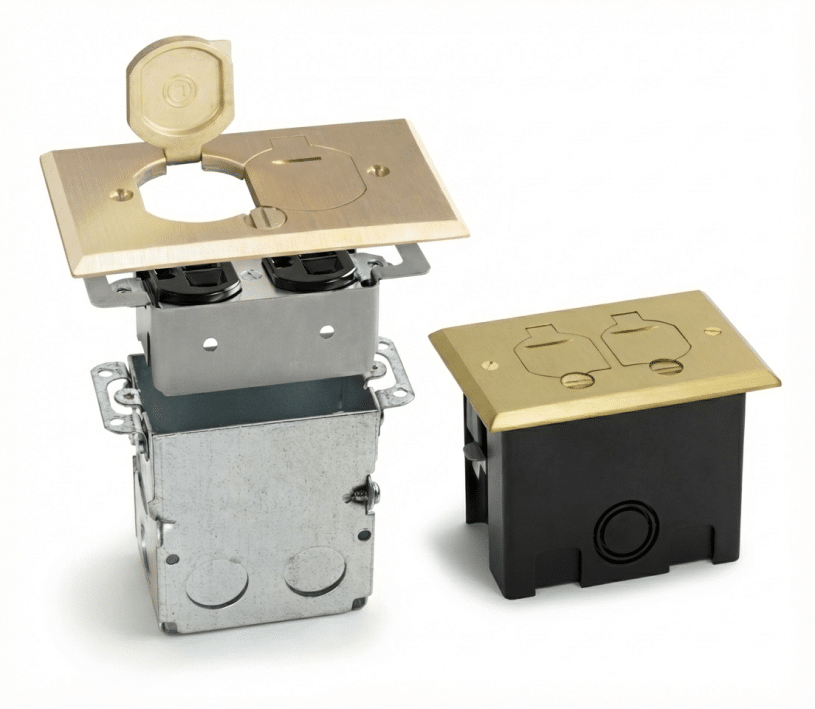

An in-slab floor box is designed to be placed inside a concrete slab before the pour takes place. The box connects to conduit during the rough-in stage, and when the slab is poured, it becomes a permanent part of the structure. After the floor is finished, the box is trimmed flush, and a decorative cover is installed.

Like poke-throughs, these boxes can deliver power, communications, audio/visual, and low-voltage services. The main distinction is that in-slab boxes are part of new construction, while poke-throughs are typically used for retrofits.

Why They Aren’t Called Poke-Throughs

The terminology is important. A poke-through earns its name because it is installed through an existing concrete floor—literally poking from one level to the next.

In-slab boxes do not poke through anything. They are embedded inside the slab during construction, fully surrounded by concrete. While they provide many of the same functions, the installation method is completely different, and that’s why they carry their own name.

Installation Process

Installing in-slab boxes requires careful planning before the concrete is poured. Here’s how it works:

- Layout Planning – Electricians mark exact locations based on room design, furniture placement, and where outlets will be most useful.

- Box Placement – The in-slab box is secured and connected to conduit. Different hub sizes allow flexibility for power and data lines.

- Concrete Pour – The slab is poured, embedding the box permanently in the floor. These boxes are engineered to withstand the weight and curing pressures of concrete.

- Trimming – Once flooring is complete, the top of the box is cut flush with the finished surface.

- Final Cover – A decorative cover assembly is attached to complete the installation.

Wiring Options

In-slab boxes support the same broad range of wiring options as poke-throughs, including:

- Power only – Standard electrical outlets.

- Power + Data – Combinations that include Ethernet, phone, or USB.

- Multi-service – A mix of power, low-voltage, and AV connections.

When power and communications share the same box, a partition must be used to separate high-voltage and low-voltage wiring, keeping the system code-compliant and safe.

Advantages of In-Slab Boxes

- Ideal for New Construction – Installed before the slab is poured, making them part of the initial design.

- Clean and Permanent – Once in place, they provide flush, discreet utility access.

- Durability – Built from PVC, composites, or treated metals, designed to last inside concrete.

- Design Flexibility – Just like poke-throughs, they support multiple services in a single box.

- Aesthetic Choices – A wide variety of covers and finishes allow them to blend into flooring seamlessly.

Limitations

- Not for Retrofits – They can only be installed during construction or major slab work.

- Permanent Placement – Once poured, the box cannot be relocated.

- Planning Required – Precise coordination between electricians and builders is essential before the concrete is placed.

Where In-Slab Boxes Are Used

Commercial Buildings – In-slab boxes distribute power and data throughout large open spaces in offices, retail stores, and classrooms. They are especially valuable in training facilities, showrooms, and open-plan offices.

Institutional Settings – Universities, libraries, and government facilities use in-slab boxes to provide flexible access to utilities in auditoriums, labs, and collaborative spaces.

Hospitality and Entertainment – Hotels, casinos, and convention centers use them in ballrooms, lobbies, and seating areas where flexible access to power and AV is required.

High-Rises – Tall commercial and mixed-use buildings benefit from in-slab boxes to provide access in tenant spaces. Since high-rises often rely on large concrete slab floors, these boxes are easy to plan into construction.

Sporting Stadiums and Arenas – Venues use in-slab boxes to supply power for concessions, ticket counters, broadcast stations, and portable event equipment.

Airports – Installed throughout gates, waiting areas, lounges, and retail spaces, in-slab boxes allow airports to serve both passengers and operations staff with discreet utility access.

Hospitals and Healthcare – In-slab boxes allow power and communications to be placed exactly where needed in patient rooms, nurse stations, diagnostic areas, and labs.

Limited Residential Use – Rare in homes, though they may be specified in high-end residences with home theaters or heavy data requirements.

Types of In-Slab Floor Boxes

- Steel or Composite Units – Heavy-duty models used in large-scale projects.

- Power Only – Dedicated to standard outlets.

- Multi-Service – Configured for power, communications, and AV, with built-in partitions.

Cover Options

Covers are what the user sees, and they play a big role in aesthetics. Common choices include:

- Brass for a warm, classic look.

- Stainless steel for modern durability.

- Bronze or powder-coated finishes for subtle color matching.

- Plastic options for budget-sensitive projects.

Hinged or gasketed covers are also available for high-traffic spaces, protecting the outlets when not in use.

Comparing In-Slab and Poke-Through

Here is a concise side-by-side comparison:

|

Feature |

In-Slab Floor Box |

Poke-Through Floor Box |

|

Installation Timing |

During slab pour |

After slab is complete |

|

Best For |

New construction |

Retrofit projects |

|

Wiring Options |

Power, data, AV, multi-service |

Power, data, AV, multi-service |

|

Flexibility After Install |

Permanent once poured |

Can be added later as needed |

|

Typical Use |

Offices, institutions, hospitality, high-rises, airports, stadiums, hospitals |

Universities, retrofits, offices, retail |

|

Core Drilling Required |

No |

Yes |

Conclusion

In-slab floor boxes provide all the utility of poke-throughs—power, data, and AV connections in the middle of open spaces—but are embedded directly into concrete during construction. This makes them a durable, clean, and permanent option for new builds.

They are especially valuable in offices, retail environments, classrooms, hospitality venues, high-rises, stadiums, airports, and hospitals where flexible access to utilities is critical. While rarely specified in homes, they may appear in high-end residences with unique data or theater requirements.

For architects, contractors, and designers, in-slab floor boxes remain one of the most effective ways to distribute utilities seamlessly in large, open-plan spaces.

Blog

Latest Insights and Trends

Explore our latest blog posts on electrical solutions.

PVC vs. Metal Floor Boxes: What Inspectors Actually Care About

Choosing between PVC and metal floor boxes often sparks debate on job sites

Where Floor Boxes Make Sense in Commercial Spaces

Offices, Retail, Hospitality, and Beyond In commercial environments, electr

Where Should Floor Boxes Be Placed in a Living Room?

Practical Guidelines for Comfort, Safety, and Design Living rooms have evo