PVC vs. Metal Floor Boxes: What Inspectors Actually Care About

Choosing between PVC and metal floor boxes often sparks debate on job sites, but inspectors are rarely focused on material preference alone. What matters most during an inspection is whether the floor box is appropriate for the application, properly listed, and installed according to code and manufacturer instructions. Understanding how inspectors evaluate these products can help contractors, designers, and builders avoid costly delays and failed inspections.

Understanding the Inspector’s Perspective

Electrical inspectors are tasked with ensuring safety, durability, and code compliance. When reviewing a floor box installation, they are not asking whether PVC or metal is better in general. Instead, they evaluate whether the selected box matches the environment it is installed in and whether it meets the applicable standards.

What Inspectors Check First

The first things inspectors typically verify are listing and labeling. Floor boxes must be listed for the specific application, whether that is in-slab, above-floor, residential, or commercial use. Inspectors also check environmental ratings, such as whether the box is approved for dry, damp, or wet locations. Finally, they confirm that the installation follows the manufacturer’s instructions, including depth, sealing, and cover type.

Where PVC Floor Boxes Make Sense

PVC floor boxes are commonly used in residential slab and in-slab applications. They perform well in dry interior environments and are often selected for homes where the traffic level is moderate and the conditions are controlled. PVC boxes can also offer corrosion resistance in certain applications, which makes them a practical choice when moisture exposure is limited and the product is properly listed for the installation.

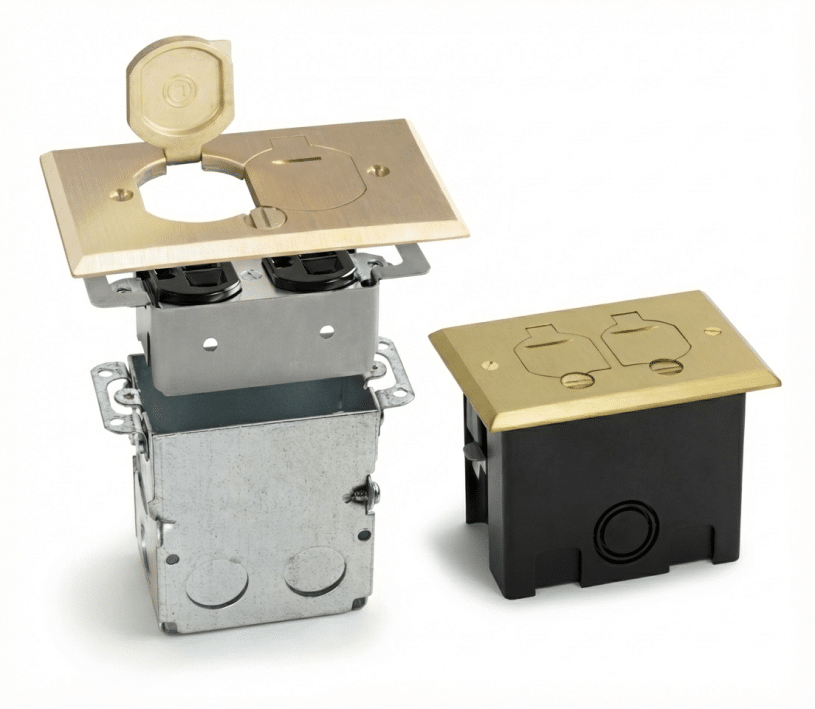

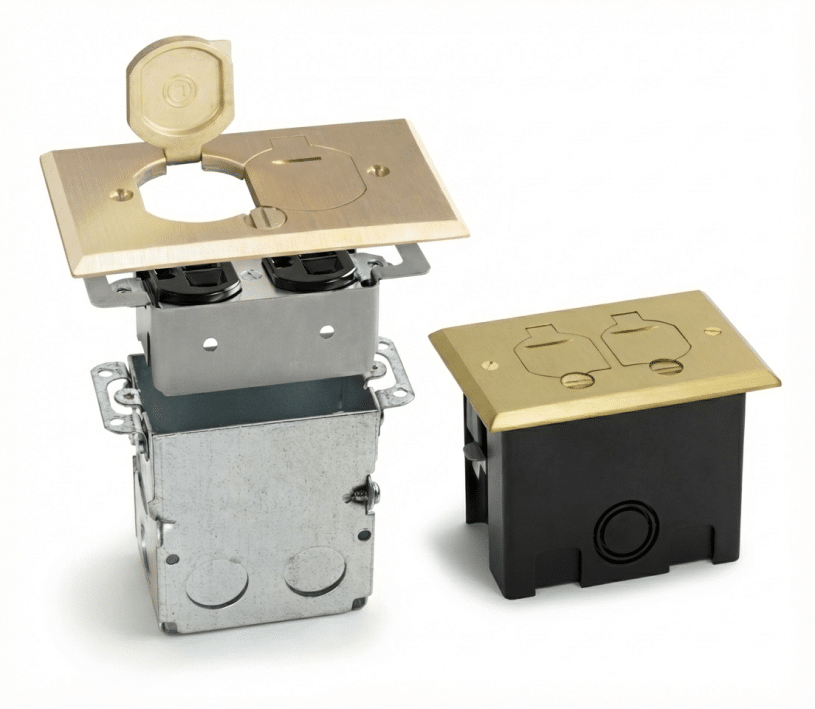

Where Metal Floor Boxes Are Preferred

Metal floor boxes are often required or strongly preferred in commercial environments. High-traffic areas, such as offices, retail spaces, and conference rooms, typically demand metal boxes due to their strength and durability. Metal boxes are also frequently specified in damp locations or fire-rated floor assemblies, where the construction type and code requirements may restrict the use of non-metallic enclosures.

Traffic Rating Is Critical

Regardless of whether a floor box is PVC or metal, inspectors pay close attention to traffic ratings. Floor boxes must be rated for foot traffic when installed in walking surfaces. A common inspection failure occurs when a box is installed in a floor but is not listed for floor use or does not carry the appropriate load rating. Material alone does not determine traffic approval; the listing does.

Moisture, Location, and Environmental Conditions

Environmental exposure often determines approval more than box material. Inspectors evaluate whether the box is suitable for the specific location, such as interior dry spaces, damp locations near exterior doors, or areas subject to cleaning or spills. Proper covers, gaskets, and seals are essential, and inspectors will verify that the entire assembly—not just the box—meets the environmental requirements.

Fire Rating and Floor Penetration Concerns

In fire-rated floor assemblies, inspectors are particularly strict. Some fire-rated designs require metal floor boxes or specific assemblies that maintain the integrity of the floor rating. In these cases, using a non-compliant box can result in rejection, even if the installation appears otherwise sound. Understanding the fire-rating requirements early in the design process helps prevent rework later.

Common Misconceptions About PVC vs. Metal

One of the most common misconceptions is that metal boxes will always pass inspection while PVC boxes will not. In reality, inspectors care about compliance, not assumptions. A properly listed PVC box installed in the correct environment can pass inspection just as easily as a metal box. Conversely, a metal box installed outside of its listing can still fail.

A Smart Contractor Strategy

Successful contractors match the floor box to the application from the start. This means reviewing environmental conditions, traffic expectations, fire ratings, and local code requirements before selecting a product. Following manufacturer instructions closely and documenting compliance can make inspections smoother and faster.

At Lew Electric, both PVC and metal floor box solutions are designed to meet code requirements across a wide range of residential and commercial applications. Understanding how inspectors evaluate these products helps ensure the right choice is made the first time. To learn more, visit www.lewelectric.com.

Final Takeaway

Inspectors are focused on safety, compliance, and proper installation. When selecting between PVC and metal floor boxes, the right choice is the one that matches the application, meets listing requirements, and is installed correctly—not simply the material itself.

Blog

Latest Insights and Trends

Explore our latest blog posts on electrical solutions.

PVC vs. Metal Floor Boxes: What Inspectors Actually Care About

Choosing between PVC and metal floor boxes often sparks debate on job sites

Where Floor Boxes Make Sense in Commercial Spaces

Offices, Retail, Hospitality, and Beyond In commercial environments, electr

Where Should Floor Boxes Be Placed in a Living Room?

Practical Guidelines for Comfort, Safety, and Design Living rooms have evo