Common Materials Used in Floor Boxes

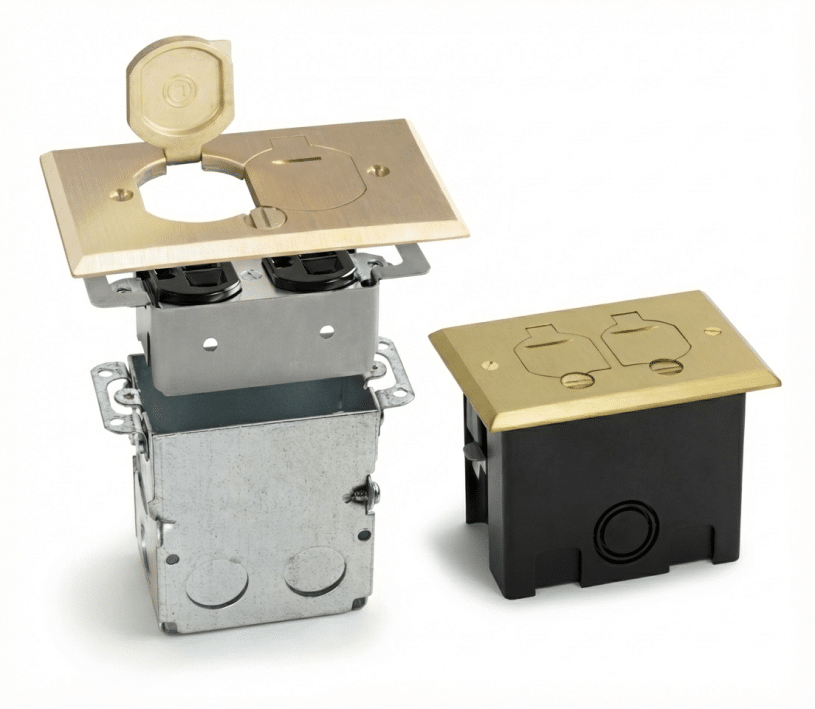

When you’re planning to add power and communications outlets to your floor, you’ll quickly discover that floor boxes come in a wide range of materials — from stamped steel and cast iron to die-cast aluminum and PVC plastic. Each material has its own strengths, code considerations, and ideal applications.

Whether you’re planning a residential remodel or outfitting a new office space, the choice of material can significantly impact installation ease, long-term durability, cost, and code compliance. Understanding these differences is essential before you make your purchase or start cutting into a slab.

At first glance, it might seem excessive that floor boxes come in so many materials. But this variety exists for two main reasons:

- Different installation environments – Floors in homes, offices, warehouses, and retail spaces vary widely in structure and accessibility. Some sit above basements or crawl spaces; others rest directly on concrete slabs.

- Building code and performance requirements – Electrical codes often dictate what materials are allowed, especially in commercial buildings or specific cities (for example, Chicago requires metal boxes only).

Each material—metal or plastic—has its own set of performance characteristics that make it more suitable for certain jobs. Let’s look more closely at each.

Stamped Steel

Stamped steel floor boxes are among the most common and affordable options used in both residential and light commercial settings.

Advantages:

- Durable and strong for general-purpose use.

- Excellent grounding and electrical continuity.

- Ideal for wood subfloors or locations above a basement.

Considerations:

- Not corrosion-resistant unless plated or painted.

- Can deform under heavy loads if not properly installed.

- Typically used in situations where the floor box isn’t directly embedded in concrete.

Stamped steel works well for upper floors of buildings or areas with raised flooring systems where access to the underside of the floor is available.

Cast Iron

Cast iron used to be the industry standard for heavy-duty commercial floor boxes. It remains a reliable choice for on-grade installations, where the floor box is embedded in a concrete slab.

Advantages:

- Incredibly strong and long-lasting.

- Handles heavy floor traffic and load stress.

- Great grounding and fire resistance.

Disadvantages:

- Very heavy—significantly increases shipping and handling costs.

- Not environmentally friendly due to the energy-intensive casting process.

- Can rust over time without protective coating.

Cast iron is still common in older buildings and industrial environments where toughness outweighs the need for lighter materials.

Die-Cast Aluminum

Die-cast aluminum floor boxes represent the modern evolution of metal floor boxes. They’re just as durable as cast iron but much lighter and more environmentally friendly.

Advantages:

- Lightweight, reducing shipping and installation costs.

- Naturally corrosion-resistant and long-lasting.

- Better environmental footprint than cast iron.

- Often just as cost-effective.

Disadvantages:

- Slightly softer metal—should not be used in ultra-heavy-duty industrial traffic zones without proper covers.

Perfect for residential or commercial projects where you want metal strength but less weight and environmental impact.

Cast Iron vs. Die-Cast Aluminum

Although both materials are approved for on-grade commercial floors, their performance and sustainability differ significantly. The chart below highlights the key distinctions:

|

Feature |

Cast Iron |

Die-Cast Aluminum |

|

Weight |

Very heavy; difficult to handle |

Lightweight and easy to manage |

|

Cost |

Comparable to aluminum |

Comparable to cast iron |

|

Durability |

Extremely strong and impact-resistant |

Highly durable yet much lighter |

|

Environmental Impact |

Energy-intensive manufacturing; higher carbon footprint |

More sustainable production with lower emissions |

|

Ease of Handling |

Heavy weight increases shipping and labor costs |

Lightweight design simplifies installation and reduces freight costs |

|

Corrosion Resistance |

Moderate; requires protective coating |

Excellent; natural oxide layer resists corrosion |

Both materials perform well, but die-cast aluminum has become the modern choice for most applications—offering equal strength with reduced weight, improved sustainability, and easier handling.

PVC (Polyvinyl Chloride)

PVC floor boxes are the go-to solution for installations directly in concrete slabs—especially in homes or buildings without a basement.

Advantages:

- Inexpensive and easy to work with.

- Corrosion-proof and lightweight.

- Can be easily cut or leveled after the concrete pour.

- Perfect for slab-on-grade construction (where there’s no basement).

Disadvantages:

- Not as strong or durable as metal boxes.

- Some cities, such as Chicago, do not allow plastic electrical boxes by code.

PVC floor boxes are ideal for residential slab homes, garages, and certain light commercial spaces where the floor is poured concrete. They allow for easy adjustment and cost savings without compromising safety when properly installed.

Final Thoughts

Selecting the right floor box material comes down to balancing installation conditions, code requirements, and personal preferences:

- PVC is ideal for homes or light-duty areas built on concrete slabs.

- Stamped steel fits upper-level installations where you can access wiring from below.

- Cast iron remains a tough, traditional choice for on-grade commercial floors.

- Die-cast aluminum offers a strong, eco-friendly, and lightweight alternative that’s becoming the go-to option for many professionals.

And as always—check local codes first. No matter how appealing a particular material might be, compliance ensures safety, longevity, and peace of mind.

Blog

Latest Insights and Trends

Explore our latest blog posts on electrical solutions.

PVC vs. Metal Floor Boxes: What Inspectors Actually Care About

Choosing between PVC and metal floor boxes often sparks debate on job sites

Where Floor Boxes Make Sense in Commercial Spaces

Offices, Retail, Hospitality, and Beyond In commercial environments, electr

Where Should Floor Boxes Be Placed in a Living Room?

Practical Guidelines for Comfort, Safety, and Design Living rooms have evo